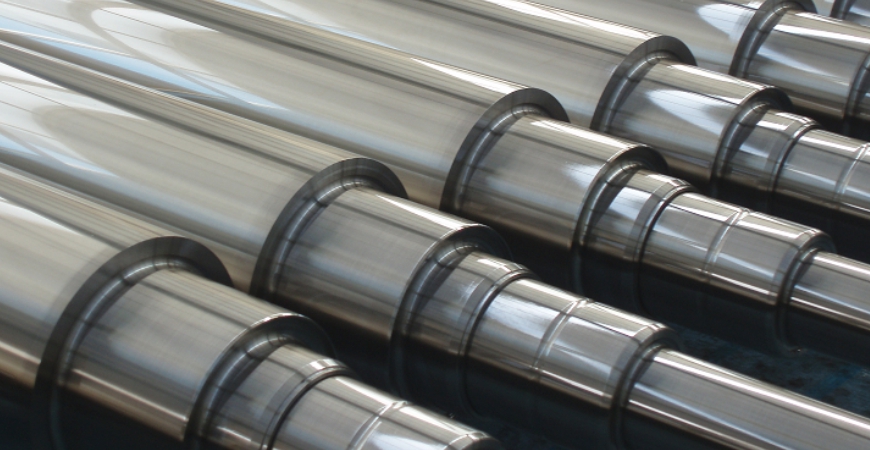

Forged Rolls Manufacturer

Forging wherein the material is hammered according to the customer's sizes & requirements, is a process in which the ingot is heated in the furnace & then forged. The forging process help in cohesiveness and strength by elongation of the grain structure, which results in material having much higher load bearing capacities as compare to casted material.Thus these rolls being so superior in wear resistance to that of Cast Steel Rolls are specially adapted for roughing and intermediate plate mills and rod or bar mill rougher. We are quality Forged Rolls Manufacturers in India.

Forging is a process in which the casted ingot is heated in the furnace & then material is hammered according to the customers sizes & requirements, thereafter heat treatment is done in normalizing / annealing furnace. we are acknowledged as one of the trustworthy Forged Rolls Manufacturers, Suppliers and Exporters in Malerkotla, India.

Forged rolls are manufactured from carbon steel, alloys steel & stainless steel, these rolls are available in primarily in forged M.S. rolls, forged en-8 rolls, forged en-9 rolls, forged en-31 rolls, forged en-42 rolls, forged class 2 & forged class 3 etc.

Our forged rolls are available with groove, bearing sizes, ready to use conditions or in semi-finished or in black forged condition, apart from rolls we offer forged product range of forged spindles, forged rings, forged shafts, forged blanks, forged cranks, forged pinion gears, flanges, forged wheels & other specially ordered products, all forged products are dispatched with essential certification, addition to that we also offer ultrasonically tested forgings for variety of applications.

The forging process help in cohesiveness and strength by elongation of the grain structure, which results in material having much higher load bearing capacities as compare to casted material forged rolls offered by us having good combination of the hardness surface with high resistance to wear, heat check and though core resistance to breakage it also has an ideal hardness profile from surface to core and very high resistance to spilling, we offer all it in accurate size, weight & finish with very quick & timely delivery.

Applications

- Suitable for All Grade Forged Cylinders, Forged Automobile & Crane Parts, Roughing Stand Forged Rolls, Forged Rolls for Stainless Steel Mills, Forged Roll for Hot Steel.

Chemical Composition

| Grade | C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% |

|---|---|---|---|---|---|---|---|---|

EN-8 |

0.35-0.45 |

0.60-1.00 |

0.10-0.35 |

0.02 MAX |

0.02 MAX |

- |

- |

- |

EN-9 |

0.50-0.60 |

0.50-0.80 |

0.05-0.35 |

0.02 MAX |

0.02 MAX |

- |

- |

- |

EN-42 |

0.70-0.85 |

0.55-0.75 |

0.10-0.40 |

0.02 MAX |

0.02 MAX |

- |

- |

- |

EN-31 |

0.9-1.2 |

0.30-0.75 |

0.10-0.35 |

0.02 MAX |

0.02 MAX |

1.0-1.6 |

|

|