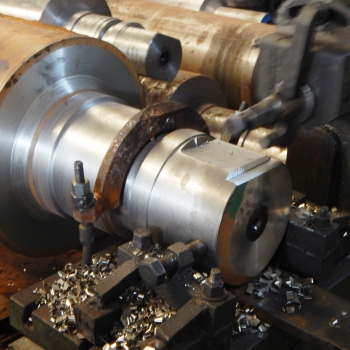

Manufacturing rolls requires many different technologies, some that we have developed ourselves, and others that are already available in the marketplace. Our foundries, steel plant, forging, machine, and heat treatment shops, are capable of manufacturing a wide range of rolls. Bench marking between our plants enables us to establish best practices and ensures that knowledge exchange is efficiently spread throughout the company. We are proud to say that we have an ultra-modern manufacturing facility assuring high quality Rolls.

In House Manufacturing Facilities

24/7 Free Customer Support.

Shree Gautam Rolls is ONE STOP SHOP bringing best Rolling Mill Rolls.

+91-99140-37677

Mob: +91-98140-07677

Email: rolls.gautam94@gmail.com